Radar is an object-detecting device which uses a pulse of radio energy to identify the range, direction, altitude, direction, and speed of both moving and fixed objects such as aircraft, ships, spacecraft, guided missiles, motor vehicles, weather formations, and terrain. The radar dish, or antenna, transmits pulses of radio waves or microwaves which bounce off any object in their path. The object returns a tiny part of the wave's energy to a dish or antenna which is usually located at the same site as the transmitter.

Radar is based on the principle of sending very long wavelength radiation (called microwaves) from an antenna, and then detecting that energy after it bounces off a remote target. The wavelength of the microwave, its polarization (vertical or horizontal orientation) and strength can be controlled at the source and measured when it returns. Many common land-cover types and materials affect the polarity and strength of the radar return differently, which helps in their identification.

The term RADAR was coined in 1940 by the US Navy as an acronym for RAdio Detection And Ranging. The term radar has since entered the English and other languages as the common noun, radar, losing all of the capitalization. In the United Kingdom, this technology was initially called RDF (Range and Direction Finding), using the same acronym as the one for Radio Direction Finding to conceal its ranging capability.

Sunday, October 31, 2010

Saturday, October 30, 2010

PS-05/A

The PS-05/A is a pulse-doppler, multimode search radar which is used in the JAS 39 Gripen fighter aircraft. The PS-05/A functions in the 8-10 GHz band and has 1 kW energy output (> 10 kW maximum output). It is composed of four parts: 1) travelling wave tube power amplifier/transmitter unit; 2) a 23 kg signal/data processor; 3) a 32 kg software-controlled exciter/receiver unit; 4) a 25 kg antenna/platform assembly. All four parts can be replaced in 30 minutes. The radar is capable of detecting, locating, identifying and automatically tracking multiple targets in the upper and lower spheres, on the ground and sea or in the air, in all weather conditions.

The D80 signal/data processor employs a software written in Pascal and incorporates a built-in test routine. To provide the required operational flexibility, low, medium and high Pulse Repetition Frequency (PRF) functions are used together with a range of waveform modes which include Air-to-Ground Ranging (AGR)A ground target ranging mode. The Doppler Beam Sharpening (DBS) is a synthetic aperture mode which employs Doppler processing and is used for high-resolution ground mapping with high angular coverage obtained via continuous antenna scanning.

The D80 signal/data processor employs a software written in Pascal and incorporates a built-in test routine. To provide the required operational flexibility, low, medium and high Pulse Repetition Frequency (PRF) functions are used together with a range of waveform modes which include Air-to-Ground Ranging (AGR)A ground target ranging mode. The Doppler Beam Sharpening (DBS) is a synthetic aperture mode which employs Doppler processing and is used for high-resolution ground mapping with high angular coverage obtained via continuous antenna scanning.

Friday, October 29, 2010

AN/APG-81

The AN/APG-81 is a solid-state active electronically scanned array radar, which was developed by Northrop Grumman Electronic Systems for the F-35 Lightning II fighter aircraft. The AN/APG-81 aims its beam by broadcasting radio energy which interferes constructively at certain angles in front of the antenna, which is fitted out with air and surface modes. The AN/APG-81 replaced the AN/APG-77 used in the F-22 Raptor aircraft. It improves on the older passive electronically scanned radars by spreading their broadcasts out across a band of frequencies, which makes it very difficult to detect over background noise. In August 2005, the APG-81 radar was flown for the first time aboard Northrop Grumman's BAC 1-11 airborne laboratory. Since then, the radar system has accumulated over 300 flight hours, maturing all five blocks of software.

More than 3,000 AN/APG-81 radars are expected to be ordered for the F-35, with production to run beyond 2035, and including large quantities of international orders. As of August 2007, 8 APG-81s have already been produced and delivered. The first three blocks of radar software have been developed, flight tested, and delivered ahead of schedule by the Northrop Grumman Corporation. Capabilities of the AN/APG-81 include the AN/APG-77's air-to-air modes plus advanced air-to-ground modes including high resolution mapping, multiple ground moving target detection and track, combat identification, electronic warfare, and ultra high bandwidth communications. The current F-22 production radar is the APG-77v1, which draws heavily on APG-81 hardware and software for its advanced air-to-ground capabilities.

AN/APG-81 Radar (Video)

More than 3,000 AN/APG-81 radars are expected to be ordered for the F-35, with production to run beyond 2035, and including large quantities of international orders. As of August 2007, 8 APG-81s have already been produced and delivered. The first three blocks of radar software have been developed, flight tested, and delivered ahead of schedule by the Northrop Grumman Corporation. Capabilities of the AN/APG-81 include the AN/APG-77's air-to-air modes plus advanced air-to-ground modes including high resolution mapping, multiple ground moving target detection and track, combat identification, electronic warfare, and ultra high bandwidth communications. The current F-22 production radar is the APG-77v1, which draws heavily on APG-81 hardware and software for its advanced air-to-ground capabilities.

AN/APG-81 Radar (Video)

S1850M Radar

Capable of automatic detection and track initiation, the S1850M is a long range, ship-based radar for wide area search. The S1850M is an upgraded variant of the Thales Nederland SMART-L radar. It is manufactured by the firm BAE Systems Integrated System Technologies (formerly AMS UK) and Thales. and advertised as being capable of tracking of up to 1,000 targets at a range of 250 miles. The S1850M is highly capable of detecting stealth targets, and is able to detect and track outer atmosphere objects at short range, making it capable of forming part of a Theatre Ballistic Missile Defence system.

The contract for initial production of the S1850M was signed in 2001: 2 for the UK, 1 for France and 1 for Italy, with a common prototype based in Toulon. In 2005 a follow-on contract was signed for 5 more for the UK, 1 more for France and 1 more for Italy. Even a stronger version of the S1850M is under testing, which is actually an updated version of the current SMART-L radar, which the Dutch Navy will call the Smart-L mk2 Radar, with even a greater search radius, but this version is still under testing. It would have a tracking range of over 800km over sea and 400km into space.

The contract for initial production of the S1850M was signed in 2001: 2 for the UK, 1 for France and 1 for Italy, with a common prototype based in Toulon. In 2005 a follow-on contract was signed for 5 more for the UK, 1 more for France and 1 more for Italy. Even a stronger version of the S1850M is under testing, which is actually an updated version of the current SMART-L radar, which the Dutch Navy will call the Smart-L mk2 Radar, with even a greater search radius, but this version is still under testing. It would have a tracking range of over 800km over sea and 400km into space.

Thursday, October 28, 2010

WSR-57

Designed in 1957 using World War II technology, the WSR-57 was the first modern weather radar. "WSR-57" stands for "Weather Surveillance Radar 1957". It was first installed at the Miami Hurricane Forecast Center, and later in other parts of the continental United States. The WSR-57 was the first generation of radars designed expressly for a national warning network.

The WSR-7 gave only coarse reflectivity data and no velocity data, which made it extremely difficult to predict tornadoes. Weather systems were traced across the radar screen using grease pencils. Forecasters had to manually turn a crank to adjust the radar's scan elevation, and needed considerable skill to judge the intensity of storms based on green blotches on the radar scope.

The military designation for the WSR-57 was AN/FPS-41. As the network of WSR-57 radars aged, operators sometimes had to scramble for spare parts no longer manufactured in the USA. The WSR-57 was eventually replaced by the WSR-74. One hundred twenty-eight of the WSR-57 and WSR-74 model radars were spread across the country as the National Weather Service's radar network until the 1990s.

The WSR-7 gave only coarse reflectivity data and no velocity data, which made it extremely difficult to predict tornadoes. Weather systems were traced across the radar screen using grease pencils. Forecasters had to manually turn a crank to adjust the radar's scan elevation, and needed considerable skill to judge the intensity of storms based on green blotches on the radar scope.

The military designation for the WSR-57 was AN/FPS-41. As the network of WSR-57 radars aged, operators sometimes had to scramble for spare parts no longer manufactured in the USA. The WSR-57 was eventually replaced by the WSR-74. One hundred twenty-eight of the WSR-57 and WSR-74 model radars were spread across the country as the National Weather Service's radar network until the 1990s.

Wednesday, October 27, 2010

Magellan XHR SEM

The Magellan XHR is the world's first extreme high resolution scanning electron microscope (SEM). The Magellan XHR model 400L renders unequaled surface-sensitive imaging performance at sub-nanometer resolution, without compromising the analytical capabilities, sample flexibility or ease of use of a traditional analytical SEM. With sub-nm resolution at voltages from 1 to 30 kV, plus a large tiltable stage for 3-D surface imaging of large or multiple samples, this revolutionary new XHR SEM allows the scientist see things he has never seen before.

Sub-nanometer resolution across the 1 to 30kV range has critical value in scientific research and industrial R&D. In addition, it is an absolute requirement in process development, monitoring and control applications in advanced semiconductor manufacturing and the electronics industry. The Magellan XHR SEM family of microscopes extends this capability to applications that were previously impossible or impractical with conventional scanning electron microscopes (SEM), transmission electron microscopes (TEM) or focused ion beam (FIB) systems.

The Magellan Family is available in two models: The Magellan XHR SEM 400, which is optimized for scientific research, and the Magellan™ XHR SEM 400L, engineered for semiconductor labs and other electronics applications. The Magellan XHR SEM 400L comes with an automated loadlock that speeds-up sample throughput, and includes a retractable solid state backscatter electron detector (SSBSED) and S2 compliance kit, all standard equipment. Both models remain highly configurable with more detectors (STEM, EDS and more), a cryostage, specialized holders and many more. An optional full environmental enclosure can be added to isolate the instrument from thermal and acoustic interferences, ensuring peak performance while relaxing site requirements and facility preparation costs.

The Magellan XHR Scanning Electron Microscope can be acquired at www.fei.com

Sub-nanometer resolution across the 1 to 30kV range has critical value in scientific research and industrial R&D. In addition, it is an absolute requirement in process development, monitoring and control applications in advanced semiconductor manufacturing and the electronics industry. The Magellan XHR SEM family of microscopes extends this capability to applications that were previously impossible or impractical with conventional scanning electron microscopes (SEM), transmission electron microscopes (TEM) or focused ion beam (FIB) systems.

The Magellan Family is available in two models: The Magellan XHR SEM 400, which is optimized for scientific research, and the Magellan™ XHR SEM 400L, engineered for semiconductor labs and other electronics applications. The Magellan XHR SEM 400L comes with an automated loadlock that speeds-up sample throughput, and includes a retractable solid state backscatter electron detector (SSBSED) and S2 compliance kit, all standard equipment. Both models remain highly configurable with more detectors (STEM, EDS and more), a cryostage, specialized holders and many more. An optional full environmental enclosure can be added to isolate the instrument from thermal and acoustic interferences, ensuring peak performance while relaxing site requirements and facility preparation costs.

The Magellan XHR Scanning Electron Microscope can be acquired at www.fei.com

Tuesday, October 26, 2010

Transmission Electron Microscope

A transmission electron microscope is a microscope which transmits a beam of electrons through an ultra thin specimen, interacting with the specimen as it passes through. An image is formed from the interaction of the electrons transmitted through the specimen; the image is magnified and focused onto an imaging device, such as a fluorescent screen, on a layer of photographic film, or to be detected by a sensor such as a CCD camera.

Transmission electron microscopes use extremely thin (0.5 µm or less) samples illuminated by the electron beam. Images are recorded by detecting the electrons that pass though the sample to a system of electromagnetic lenses which focus and enlarge the image on the fluorescent screen, photographic film or digital camera. Magnifications beyond 1,000,000x are attainable with a transmission electron microscope.

Transmission electron microscopes use extremely thin (0.5 µm or less) samples illuminated by the electron beam. Images are recorded by detecting the electrons that pass though the sample to a system of electromagnetic lenses which focus and enlarge the image on the fluorescent screen, photographic film or digital camera. Magnifications beyond 1,000,000x are attainable with a transmission electron microscope.

Scanning Electron Microscope

The scanning electron microscope is a type of electron microscope that images the sample surface by scanning it with a high-energy beam of electrons in a raster scan pattern. Scanning Electron Microscopes (SEM) are used for inspecting topographies of materials with a magnification range that encompasses that of optical microscopy and extends it to the nanoscale. The electrons interact with the atoms that make up the sample producing signals that contain information about the sample's surface topography, composition and other properties such as electrical conductivity. The scanning electron microscope produces different types of signals which include secondary electrons, back-scattered electrons (BSE), characteristic X-rays, light (cathodoluminescence), specimen current and transmitted electrons. These signals result from interactions of the electron beam with atoms at or near the surface of the sample.

Scanning electron microscope micrographs have a large depth of field yielding a characteristic three-dimensional appearance useful for understanding the surface structure of a sample. A wide range of magnifications is possible, from about 10 times (about equivalent to that of a powerful hand-lens) to more than 500,000 times, about 250 times the magnification limit of the best light microscopes.

In a typical Scanning electron microscope (SEM), an electron beam is thermionically emitted from an electron gun fitted with a tungsten filament cathode. Tungsten is normally used in thermionic electron guns because it has the highest melting point and lowest vapour pressure of all metals, thereby allowing it to be heated for electron emission, and because of its low cost. Other types of electron emitters include lanthanum hexaboride (LaB6) cathodes, which can be used in a standard tungsten filament SEM if the vacuum system is upgraded and field emission guns (FEG), which may be of the cold-cathode type using tungsten single crystal emitters or the thermally-assisted Schottky type, using emitters of zirconium oxide.

Magellan Scanning Electron Microscope

Scanning electron microscope micrographs have a large depth of field yielding a characteristic three-dimensional appearance useful for understanding the surface structure of a sample. A wide range of magnifications is possible, from about 10 times (about equivalent to that of a powerful hand-lens) to more than 500,000 times, about 250 times the magnification limit of the best light microscopes.

In a typical Scanning electron microscope (SEM), an electron beam is thermionically emitted from an electron gun fitted with a tungsten filament cathode. Tungsten is normally used in thermionic electron guns because it has the highest melting point and lowest vapour pressure of all metals, thereby allowing it to be heated for electron emission, and because of its low cost. Other types of electron emitters include lanthanum hexaboride (LaB6) cathodes, which can be used in a standard tungsten filament SEM if the vacuum system is upgraded and field emission guns (FEG), which may be of the cold-cathode type using tungsten single crystal emitters or the thermally-assisted Schottky type, using emitters of zirconium oxide.

Magellan Scanning Electron Microscope

Monday, October 25, 2010

Petrographic Microscope

A petrographic microscope is an optical microscope commonly employed in petrology and optical mineralogy to identify rocks and minerals in thin sections. Petrographic microscopes are built with optical parts that do not add unwanted polarizing effects due to strained glass, or polarization by reflection in prisms and mirrors. These special parts add to the cost and complexity of the microscope. Nevertheless, a "simple polarizing" microscope is easily made by adding inexpensive polarizing filters to a standard biological microscope, often with one in a filter holder beneath the condenser, and a second inserted beneath the head or eyepiece.

The two filters of the petrographic microscope have their polarizing planes oriented perpendicular to one another. When only an isotropic material such as air, water, or glass exists between the filters, all light is blocked. However, most crystalline materials and minerals change the polarizing light directions, which allows some of the altered light to pass through the analyzer to the viewer. Using one polarizer allows for looking at the slide in plane polarized light, while using two allows for analysis under cross polarized light.

A particular light pattern on the upper lens surface of the objectives is created as an conoscopic interference pattern characteristic of uniaxial and biaxial minerals, and produced with convergent polarized light. To observe the interference figure, true petrographic microscopes usually include an accessory called a Bertrand lens, which focuses and enlarges the figure. It is also possible to remove an eyepiece lens to make a direct observation of the objective lens surface.

The two filters of the petrographic microscope have their polarizing planes oriented perpendicular to one another. When only an isotropic material such as air, water, or glass exists between the filters, all light is blocked. However, most crystalline materials and minerals change the polarizing light directions, which allows some of the altered light to pass through the analyzer to the viewer. Using one polarizer allows for looking at the slide in plane polarized light, while using two allows for analysis under cross polarized light.

A particular light pattern on the upper lens surface of the objectives is created as an conoscopic interference pattern characteristic of uniaxial and biaxial minerals, and produced with convergent polarized light. To observe the interference figure, true petrographic microscopes usually include an accessory called a Bertrand lens, which focuses and enlarges the figure. It is also possible to remove an eyepiece lens to make a direct observation of the objective lens surface.

Sunday, October 24, 2010

Celestron Biological Microscope M44102

The Celestron biological microscope is a precision optical microscope made of high quality materials designed to be used in biochemical laboratories. It is produced by the American firm Celestron, whose headquarters are in California. The Celestron biological microscope model 44102 consists of three acromatic objectives (4x=40power, 10x=100power, 40x=400power), a plain stage with spring-loaded clips, an arm with an angle choice from 0 to 60º, a focuser with coarse and fine focus knobs and rack and pinion safety stops, a 50mm plano-concave mirror, an eyepiece, a nosepiece, a condenser, and a disc diaphragm with five aperture sizes.

The Celestron microscope has a built-in plano-concave illumination mirror which allows the biochemist to illuminate the specimen from the bottom by reflecting an external light source to the stage. The mirror has a flat side and a concave side. The concave side will concentrate more light onto the specimen than the flat side.

Specifications

-400x Power Biological Microscope

-10x Eyepiece

-4x, 10x, and 40x Objective Lenses

-Fully Coated Glass Optics

-All Metal Body with Monocular Head

-50 mm (2") Mirror Illumination

-Condenser

-5-position Disc Diaphragm

-Powers Available - 40x, 100x, and 400x

-Coarse and Fine Focus Knobs

-Stage with Stage Clips

-Five Prepared Slides

The Celestron microscope has a built-in plano-concave illumination mirror which allows the biochemist to illuminate the specimen from the bottom by reflecting an external light source to the stage. The mirror has a flat side and a concave side. The concave side will concentrate more light onto the specimen than the flat side.

Specifications

-400x Power Biological Microscope

-10x Eyepiece

-4x, 10x, and 40x Objective Lenses

-Fully Coated Glass Optics

-All Metal Body with Monocular Head

-50 mm (2") Mirror Illumination

-Condenser

-5-position Disc Diaphragm

-Powers Available - 40x, 100x, and 400x

-Coarse and Fine Focus Knobs

-Stage with Stage Clips

-Five Prepared Slides

Saturday, October 23, 2010

Metallographic Microscope

A metallographic microscope is a high power compound microscope with objectives of various magnifications on a turret that rotates them into place. Common magnifications are 100x up to 1000x. It is used for examining the metallic grain structures of heat treated metals as well as studying composite materials. A metallographic microscope is also used in metal foundries for inspection of the cast metal samples. Also known as metallurgical microscope, this type of microscope uses reflecting light that travels through the microscope objective. This is known as epi-illumination. Light in a dissecting stereo microscope is also reflected but it comes from an illumination source from the side, or sometimes is coaxial. In coaxial illumination, the light comes along the same axis as the objective by means of a prism located within the microscope head. Light enters the side of the prism and is reflected downward to the specimen. Still, the light does not travel through the objective as it does in the metallographic microscope.

Friday, October 22, 2010

Leitz Metalloplan Microscope

The Leitz Metalloplan is a largefield metallographic microscope produced by Leitz GmbH in the 1970s. The Metalloplan is equipped with LINNIK interferometry unit that includes 10x and 20x infinity corrected paired optic sets. The Metalloplan stand rests on a four built-in vibration damping special plastic support. The co-axial fine and coarse adjustment acts directly on the object stage. The fine adjustment operates throughout a total travel of 40mm. One interval to the fine adjustment drum corresponds to 1 micron.

The Metalloplan's largefield binocular tube with vertical photo tube is joined to the stand by means of a bayonet lock. It can be rotated through 360º. The mechanical tube length compensator built into the tube maintains simultaneous focusing in the film plane and eyepiece for all interpopullary distances. A beam splitter in the tube directs 80% of the total light into the photo-tube and 20% into the eyepiece tube. The beam splitter of the Metalloplan can be swung out of the optical path so that the full light flux is directed into the eyepiece tubes for observation. The eyepiece tubes were designed to accept largefield eyepieces of 30mm diameter. The 23.2mm diameter Periplan eyepieces can be used with adapters.

The object stage is interchangeable on a dovetail slide and can be lowered considerable for large objects. The co-axial control of the stage must be operated from the right. The vertical illuminator can be intercanged horizontally without the need for lowering the object stage. The light collar between the vertical illuminator and the light aperture in the stand has two filter slots. The standard outfit of the Metalloplan metallographic microscope includes a Lamp Housing 100. Like the Lamp Housing 250, or mirror housing, it is directly joined to the microscope by means of a bayonet lock.

The Metalloplan's largefield binocular tube with vertical photo tube is joined to the stand by means of a bayonet lock. It can be rotated through 360º. The mechanical tube length compensator built into the tube maintains simultaneous focusing in the film plane and eyepiece for all interpopullary distances. A beam splitter in the tube directs 80% of the total light into the photo-tube and 20% into the eyepiece tube. The beam splitter of the Metalloplan can be swung out of the optical path so that the full light flux is directed into the eyepiece tubes for observation. The eyepiece tubes were designed to accept largefield eyepieces of 30mm diameter. The 23.2mm diameter Periplan eyepieces can be used with adapters.

The object stage is interchangeable on a dovetail slide and can be lowered considerable for large objects. The co-axial control of the stage must be operated from the right. The vertical illuminator can be intercanged horizontally without the need for lowering the object stage. The light collar between the vertical illuminator and the light aperture in the stand has two filter slots. The standard outfit of the Metalloplan metallographic microscope includes a Lamp Housing 100. Like the Lamp Housing 250, or mirror housing, it is directly joined to the microscope by means of a bayonet lock.

Thursday, October 21, 2010

Optical Microscope

An optical microscope is a high-precision optical instrument which uses a lens or a combination of lenses to produce highly magnified images of small specimens or objects, specially when they are too small to be seen with the naked eye. A light source is used (either by mirrors or lamps) to make it easier to see the subject matter. Microscopy is the use of a microscope or laboratory investigation by a microscope.

There is no one person who invented the microscope as several different inventors experimented with theories and ideas and developed different parts of the concept as they evolved to what is today microscopes. About 1590, two Dutch spectacles makers, Zacharias Janssen and his son Hans, experimented with a crude concept of a microscope which enlarged objects 10x to 30x. In 1609, Galileo improved on the principle of lenses and added a focusing device to improve somewhat on what the Janssens had done previously.

These rudimentary optical instrument did not change much until the 1670s. A Dutchman, Anton Leeuwenhoek, is considered the father of microscope because the advances he made in microscope design and use. He worked as an aprentice in dry goods store where magnifying lenses were used to count the threads in cloth. Anton was inspired by these glasses and taught himself new methods for grinding and polishing small lenses which magnified up to 270x. This led to the first practical microscopes. In 1674, Anton Leeuwenhoek was the first man to see and discribe bacteria, yeast, and plants in a drop of water.

There are two basic configurations of the conventional optical microscope, the simple (one lens) and compound (many lenses). A simple microscope is a microscope that uses only one lens for magnification, and is the original design of optical microscope. Van Leeuwenhoek's microscopes consisted of a small, single converging lens mounted on a brass plate, with a screw mechanism to hold the sample or specimen to be examined. A compound microscope is a microscope which uses multiple lenses to collect light from the sample and then a separate set of lenses to focus the light into the eye or camera. Compound microscopes are heavier, larger and more expensive than simple microscopes due to the increased number of lenses used in construction. The main advantages of multiple lenses are improved numerical aperture, reduced chromatic aberration and exchangeable objective lenses to adjust the magnification.

There is no one person who invented the microscope as several different inventors experimented with theories and ideas and developed different parts of the concept as they evolved to what is today microscopes. About 1590, two Dutch spectacles makers, Zacharias Janssen and his son Hans, experimented with a crude concept of a microscope which enlarged objects 10x to 30x. In 1609, Galileo improved on the principle of lenses and added a focusing device to improve somewhat on what the Janssens had done previously.

These rudimentary optical instrument did not change much until the 1670s. A Dutchman, Anton Leeuwenhoek, is considered the father of microscope because the advances he made in microscope design and use. He worked as an aprentice in dry goods store where magnifying lenses were used to count the threads in cloth. Anton was inspired by these glasses and taught himself new methods for grinding and polishing small lenses which magnified up to 270x. This led to the first practical microscopes. In 1674, Anton Leeuwenhoek was the first man to see and discribe bacteria, yeast, and plants in a drop of water.

There are two basic configurations of the conventional optical microscope, the simple (one lens) and compound (many lenses). A simple microscope is a microscope that uses only one lens for magnification, and is the original design of optical microscope. Van Leeuwenhoek's microscopes consisted of a small, single converging lens mounted on a brass plate, with a screw mechanism to hold the sample or specimen to be examined. A compound microscope is a microscope which uses multiple lenses to collect light from the sample and then a separate set of lenses to focus the light into the eye or camera. Compound microscopes are heavier, larger and more expensive than simple microscopes due to the increased number of lenses used in construction. The main advantages of multiple lenses are improved numerical aperture, reduced chromatic aberration and exchangeable objective lenses to adjust the magnification.

Wednesday, October 20, 2010

General Electric TF34

The TF34 is a twin-shaft turbofan jet engine developed by General Electric to power the S-3 Viking and the A-10 Thunderbolt II. The GE TF34 consists of a single-stage fan, 14-stage high pressure (HP) compressor, 4-stage low pressure (LP) turbine, a 2-stage high pressure (HP) turbine, and an annular combustor. The TF34-GE-400A is rated at 9,275 lbf (41.26 KN) static thrust. Designed in 1967, the TF34 first flew in 1971. It is used by the U.S. Air Force A-10 and had a growing civil market. The civil version of the TF34 was designated the CF34.

More than 460 TF34 engines are in service today with the US Navy and more than 1,050 are in service with the US Air Force. With more than 11 million fleet hours, the TF34 is projected to remain in service beyond 2028.

Specifications of the General Electric TF34

Type: axial flow bypass turbofan engine

Length: 2.62 m

Diameter: 1.12 m

Dry weight: 758 kg

Compressor: 14-stage compressor

Turbine: 4-stage LP turbine; 2-stage HP turbine

Combustor: annular

Maximum thrust: 9,275 lb

Mass flow: 338 lbs/sec

Power-to-weight ratio:

More than 460 TF34 engines are in service today with the US Navy and more than 1,050 are in service with the US Air Force. With more than 11 million fleet hours, the TF34 is projected to remain in service beyond 2028.

Specifications of the General Electric TF34

Type: axial flow bypass turbofan engine

Length: 2.62 m

Diameter: 1.12 m

Dry weight: 758 kg

Compressor: 14-stage compressor

Turbine: 4-stage LP turbine; 2-stage HP turbine

Combustor: annular

Maximum thrust: 9,275 lb

Mass flow: 338 lbs/sec

Power-to-weight ratio:

Tuesday, October 19, 2010

Allison J102

The Allison J102 was a supersonic missile turbojet engine developed by the Allison Engine Company. The J102 was an axial flow turbojet which was first run in March 1991. In 1997 it was being considered for use in a sea-skimming supersonic target for the United States Navy.

The J102 was a reaction engine which produced thrust by the expulsion of a high-speed gas exhaust. It was created by high pressure (10-200 bar) combustion of solid propellants, consisting of fuel and oxidiser components, within a combustion chamber. The fluid exhaust was then passed through a propelling nozzle which typically used the heat energy of the gas to accelerate the exhaust to very high speed, and the reaction to this pushed the engine in the opposite direction.

The J102 was a reaction engine which produced thrust by the expulsion of a high-speed gas exhaust. It was created by high pressure (10-200 bar) combustion of solid propellants, consisting of fuel and oxidiser components, within a combustion chamber. The fluid exhaust was then passed through a propelling nozzle which typically used the heat energy of the gas to accelerate the exhaust to very high speed, and the reaction to this pushed the engine in the opposite direction.

Monday, October 18, 2010

Afterburner (Jet Engine)

A jet engine afterburner is an extended exhaust section which contains extra fuel injectors. When the afterburner is turned on, fuel is injected, which ignites readily due to the relatively high temperature of the incoming gases. The resulting combustion process increases the afterburner exit (nozzle entry) temperature significantly, resulting in a steep increase in engine net thrust. Thus, jet engines achieve additional thrust by directly injecting fuel at the engine exhaust. The afterburner gives the aircraft a rocket-like boost as the fuel ignites in the exhaust chamber. The tradeoff is higher fuel consumption, a greater amount of heat, and consequently, greater visibility to the enemy.

The purpose of an afterburner is to provide a temporary increase in thrust, both for supersonic flight and for takeoff, as the high wing loading typical of supersonic aircraft designs means that take-off speed is very high. On military aircraft the extra thrust is also useful for combat situations. This is achieved by injecting additional fuel into the jet pipe downstream of the turbine. The advantage of afterburning is significantly increased thrust; the disadvantage is its very high fuel consumption and inefficiency, though this is often regarded as acceptable for the short periods during which it is usually used.

The purpose of an afterburner is to provide a temporary increase in thrust, both for supersonic flight and for takeoff, as the high wing loading typical of supersonic aircraft designs means that take-off speed is very high. On military aircraft the extra thrust is also useful for combat situations. This is achieved by injecting additional fuel into the jet pipe downstream of the turbine. The advantage of afterburning is significantly increased thrust; the disadvantage is its very high fuel consumption and inefficiency, though this is often regarded as acceptable for the short periods during which it is usually used.

Afterburner Run on a Jet Aircraft

Sunday, October 17, 2010

Rolls Royce/Snecma Olympus 593

The Rolls-Royce/Snecma Olympus 593 was an axial-flow turbojet engine which was developed by the Birtish firm Rolls Royce and the French Snecma to power the Concorde aircraft. The Olympus 593 consisted of a seven-stage low pressure compressor, a seven-stage high pressure compressor, a single-stage high pressure turbine, and a single-stage low pressure turbine. It had an annular chamber with sixteen vaporizing burners, each with twin outlets.

The jet engine draws air in at the front and compresses it. The air then combines with fuel and the engine burns the resulting mixture. The combustion greatly increases the volume of the gases which are then exhausted out of the rear of the engine. The Olympus 593 engine took this gas jet and passed it through straightening vanes - to remove swirl. This gas jet then entered the afterburning jet pipe where a ring of fuel injectors sprayed fuel onto the hot exhaust gases. The resulting combustion greatly improved thrust, although it also led to high fuel consumption. The afterburner was thus only used at takeoff and from just below Mach 1 up to Mach 1.7, the engine supercruised above that speed.

Using the BAC TSR-2's Olympus 320 as a basis for development, the Olympus 593 project began in 1964. Bristol Siddeley of the UK and Snecma Moteurs of France were to share the project. In 1966, Rolls Royce acquired Bristol Siddeley and continued with the project. Development of the original Olympus and engine accessories was under Bristol Siddeley, while Snecma was responsible for the variable engine inlet system, the exhaust nozzle/thrust reverser, the afterburner and the noise attenuation system. Britain was to have a larger share in production of the Olympus 593 as France had a larger share in fuselage production.

Specifications

Type: axial-flow jet engine

Length: 4039 mm (159 in)

Diameter: 1212 mm (47.75 in)

Dry weight: 3175 kg (7,000 lb)

Compressor: Axial flow, 7-stage low pressure, 7-stage high pressure

Turbine: High pressure single stage, low pressure single stage

Combustors: Nickel alloy construction annular chamber, 16 vaporizing burners, each with twin outlets

Maximum thrust: wet: 169.2 kN (38,050 lbf) dry: 139.4 kN (31,350 lbf)

Overall pressure ratio: 15.5:1

Specific fuel consumption: 1.195 (cruise), 1.39 (SL) lb/(h·lbf)

Thrust-to-weight ratio: 5.4:1

The jet engine draws air in at the front and compresses it. The air then combines with fuel and the engine burns the resulting mixture. The combustion greatly increases the volume of the gases which are then exhausted out of the rear of the engine. The Olympus 593 engine took this gas jet and passed it through straightening vanes - to remove swirl. This gas jet then entered the afterburning jet pipe where a ring of fuel injectors sprayed fuel onto the hot exhaust gases. The resulting combustion greatly improved thrust, although it also led to high fuel consumption. The afterburner was thus only used at takeoff and from just below Mach 1 up to Mach 1.7, the engine supercruised above that speed.

Using the BAC TSR-2's Olympus 320 as a basis for development, the Olympus 593 project began in 1964. Bristol Siddeley of the UK and Snecma Moteurs of France were to share the project. In 1966, Rolls Royce acquired Bristol Siddeley and continued with the project. Development of the original Olympus and engine accessories was under Bristol Siddeley, while Snecma was responsible for the variable engine inlet system, the exhaust nozzle/thrust reverser, the afterburner and the noise attenuation system. Britain was to have a larger share in production of the Olympus 593 as France had a larger share in fuselage production.

Specifications

Type: axial-flow jet engine

Length: 4039 mm (159 in)

Diameter: 1212 mm (47.75 in)

Dry weight: 3175 kg (7,000 lb)

Compressor: Axial flow, 7-stage low pressure, 7-stage high pressure

Turbine: High pressure single stage, low pressure single stage

Combustors: Nickel alloy construction annular chamber, 16 vaporizing burners, each with twin outlets

Maximum thrust: wet: 169.2 kN (38,050 lbf) dry: 139.4 kN (31,350 lbf)

Overall pressure ratio: 15.5:1

Specific fuel consumption: 1.195 (cruise), 1.39 (SL) lb/(h·lbf)

Thrust-to-weight ratio: 5.4:1

Saturday, October 16, 2010

Pratt & Whitney J75

The J75 was an axial-flow, twin-spool, turbojet engine developed by Pratt & Whitney from the J57. The J75 powered the F-105 Thunderchief, Boeing 707, F-106 Delta Dart, and the Lockheed U2. It first ran on an aircraft in 1955. The Pratt & Whitney could produce up to 24,500 lbf thrust. In civilian service, it was known as the JT4A and the GG4, which were used in a variety of stationary power generation applications.

After its relatively short lifetime in the aircraft role, the J75 found more enduring use in the naval role, where it was produced in a variety of models between 18,000 and 22,000 hp. Well-known uses include the first all-turbine warships, the Canadian Iroquois class destroyers, as well as the United States Coast Guard's Hamilton class cutters, and it was considered for the US Navy's Asheville class gunboat.

After its relatively short lifetime in the aircraft role, the J75 found more enduring use in the naval role, where it was produced in a variety of models between 18,000 and 22,000 hp. Well-known uses include the first all-turbine warships, the Canadian Iroquois class destroyers, as well as the United States Coast Guard's Hamilton class cutters, and it was considered for the US Navy's Asheville class gunboat.

Friday, October 15, 2010

Allison J71

The Allison J71 was an axial-flow jet engine, designed and built by Allison Engine Company in the United States. The development of the J71 began in 1948 as a modified J35 and was originally designated the J35-A-23. The Allison J71 turbojet powered the Douglas B-66 Destroyer and the McDonnell F3H-2 Demon after the failed Westinghouse J40 proved unworkable. The prototype P6M SeaMasters were also fitted with this engine.

Specifications for the Allison J71-A-2E

Type: axial-flow turbojet with afterburner

Length: 23.9 ft

Diameter: 3.5 ft

Weight: 1,855 kg

Compressor: 16-stage axial compressor

Turbine: 3-stage

Thrust: 14,000 lb (62.3 kN) with afterburner

Specifications for the Allison J71-A-2E

Type: axial-flow turbojet with afterburner

Length: 23.9 ft

Diameter: 3.5 ft

Weight: 1,855 kg

Compressor: 16-stage axial compressor

Turbine: 3-stage

Thrust: 14,000 lb (62.3 kN) with afterburner

Thursday, October 14, 2010

Rolls-Royce RB.183 Tay

The Rolls-Royce RB.183 Tay is a twin-spool, high bypass turbofan engine manufactured by Rolls Royce for the Fokker 70 and Fokker 100 aircraft. The RB.183 Tay consists of a twenty-two blade titanium fan, three-stage Intermediate pressure compressor, twelve-stage High pressure compressor, two-stage high pressure turbine, and three-stage low pressure turbine. This aircraft engine was developed from the RB.163 Spey, using scaled down low-pressure components from the RB.211 to produce versions with a bypass ratio of 3.1:1 or greater. The engine was first run in August 1984.

Specifications for the Rolls Royce RB.183 Tay

Type: high bypass turbofan jet engine

Length: 94.7 in (2405.4 mm)

Diameter: 44 in (1117.6 mm) (fan diameter)

Dry weight: 3,310 lb (1501.4 kg)

Bypass ratio: 3.04

Compressor: Single stage fan, 3-stage LP compressor and 12-stage HP compressor

Turbine: 2-stage HP turbine and 3-stage LP turbine

Combustors: 10 cannular combustion chambers

Maximum thrust: 13,850 lbf (62.82 kN)

Turbine inlet temperature: 735 degrees C (maximum continuous)

Thrust-to-weight ratio: 4.2

Rolls-Royce Tay

Specifications for the Rolls Royce RB.183 Tay

Type: high bypass turbofan jet engine

Length: 94.7 in (2405.4 mm)

Diameter: 44 in (1117.6 mm) (fan diameter)

Dry weight: 3,310 lb (1501.4 kg)

Bypass ratio: 3.04

Compressor: Single stage fan, 3-stage LP compressor and 12-stage HP compressor

Turbine: 2-stage HP turbine and 3-stage LP turbine

Combustors: 10 cannular combustion chambers

Maximum thrust: 13,850 lbf (62.82 kN)

Turbine inlet temperature: 735 degrees C (maximum continuous)

Thrust-to-weight ratio: 4.2

Rolls-Royce Tay

Wednesday, October 13, 2010

Rolls-Royce Trent 700

The Rolls-Royce Trent 700 is an axial-flow, tripple-spool, turbofan engine which was developed by Rolls Royce from the RB.211 to power the Airbus 330. It belongs to the family of Trent engines. The Trent 700 first ran in August 1990, and certification was achieved in January 1994. 90 minutes ETOPS approval was achieved in March 1995, and this was extended to 120 minutes in December 1995 and 180 minutes in May 1996.

Specifications for the Rolls Royce Trent 700

Type: Triple-spool high bypass turbofan

Length: 3.91 m (154 in)

Diameter: 2.47 m (97 in)

Dry weight:

Bypass ratio: 5.0:1

Compressor: Eight-stage IP compressor, six-stage HP compressor

Turbine: Single-stage HP turbine, single-stage IP turbine, four-stage LP turbine

Combustors: Single annular combustor with 24 fuel injectors

Specifications for the Rolls Royce Trent 700

Type: Triple-spool high bypass turbofan

Length: 3.91 m (154 in)

Diameter: 2.47 m (97 in)

Dry weight:

Bypass ratio: 5.0:1

Compressor: Eight-stage IP compressor, six-stage HP compressor

Turbine: Single-stage HP turbine, single-stage IP turbine, four-stage LP turbine

Combustors: Single annular combustor with 24 fuel injectors

Rolls Royce Trent Certification

Tuesday, October 12, 2010

Rolls Royce Pegasus

The Rolls-Royce Pegasus was a twin-spool turbofan engine which was developed by Bristol Siddeley to power the Hawker Siddeley Harrier and the BAE Sea Harrier aircraft. The Pegasus first ran in September 1959, but its first and difficult transition from static hover to conventional flight took place on September 8, 1961. It was manufactured by Rolls Royce Plc, totaling over 1,250 engines in different versions: Pegasus 2; 5; 6, which was built for the first Harriers (19,000lbf), entering service 1969; 10; 11, which powered the RAF's Hawker Siddeley Harrier GR.3.

The Rolls Royce Pegasus was a two-shaft design, featuring a 3-stage low pressure compressor and a 8-stage high pressure compressor, driven by a 2-stage low pressure and a 2-stage high pressure turbine respectively. Unusually the low pressure and high pressure spools rotate in opposite directions to greatly reduce the gyroscopic effects which would otherwise hamper low speed handling. The engine utilizes a simple thrust vectoring system with four swivelling nozzles, giving the Harrier thrust both for lift and forward propulsion, allowing for STOVL flight.

Specifications for the Rolls-Royce Pegasus 11

Type: twin-spool turbofan

Length: 137 in (3.480 m)

Diameter: 48 in (1.219 m)

Dry weight: 3,960 lb (1,796 kg)

Compressor: 3-stage low pressure, 8-stage high pressure axial flow

Turbine: 2-stage low pressure, 2-stage high pressure

Combustors: annular

Maximum thrust: 23,800 lbf (106 kN)

Overall pressure ratio: 16.3:1

Specific fuel consumption: 0.76 lb/lbf-hr

Thrust-to-weight ratio: 6:1

The Rolls Royce Pegasus was a two-shaft design, featuring a 3-stage low pressure compressor and a 8-stage high pressure compressor, driven by a 2-stage low pressure and a 2-stage high pressure turbine respectively. Unusually the low pressure and high pressure spools rotate in opposite directions to greatly reduce the gyroscopic effects which would otherwise hamper low speed handling. The engine utilizes a simple thrust vectoring system with four swivelling nozzles, giving the Harrier thrust both for lift and forward propulsion, allowing for STOVL flight.

Specifications for the Rolls-Royce Pegasus 11

Type: twin-spool turbofan

Length: 137 in (3.480 m)

Diameter: 48 in (1.219 m)

Dry weight: 3,960 lb (1,796 kg)

Compressor: 3-stage low pressure, 8-stage high pressure axial flow

Turbine: 2-stage low pressure, 2-stage high pressure

Combustors: annular

Maximum thrust: 23,800 lbf (106 kN)

Overall pressure ratio: 16.3:1

Specific fuel consumption: 0.76 lb/lbf-hr

Thrust-to-weight ratio: 6:1

Monday, October 11, 2010

Rolls-Royce BR710

The Rolls-Royce BR710 was an axial-flow turbofan engine manufactured by Rolls Royce Deutschland. The BR710 ran for the first time in September 1994. It was composed of a 48in-diameter single stage fan, which was driven by a two-stage low pressure turbine, supercharging a ten-stage high pressure compressor and driven by a two-stage, air-cooled, high prussure turbine.

The BR710 was a twin shaft turbofan, entered service on the Gulfstream V aircraft in 1997 and the Bombardier Global Express in 1998. This version has also been selected to power the Gulfstream G550.

Specifications

Fan Diameter: 48.0 inches

Overall Length: 134.0 inches

Dry Weight: 4,640 lb

Thrust: 14,750-15,500 lb

The BR710 was a twin shaft turbofan, entered service on the Gulfstream V aircraft in 1997 and the Bombardier Global Express in 1998. This version has also been selected to power the Gulfstream G550.

Specifications

Fan Diameter: 48.0 inches

Overall Length: 134.0 inches

Dry Weight: 4,640 lb

Thrust: 14,750-15,500 lb

Sunday, October 10, 2010

Pratt & Whitney PW6000

The PW6000 is a turbofan engine developed by Pratt & Whitney to power the Airbus A318. It entered service in 2007 with a design thrust range of 18,000 to 24,000 lbf (82 to 109 kN). The Pratt & Whitney PW6000 is a high-bypass turbofan which was designed to significantly reduce maintenance cost and achieve weight and fuel consumption savings.

Originally the new PW6000 had a 5-stage high-pressure compressor, but tests revealed that this initial high pressure compressor did not meet promised fuel burn performance. To address the problem, Pratt & Whitney re-certified an updated design using a 6-stage high pressure compressor designed by MTU Aero Engines in order to achieve promised performance.

Specifications for the PW6000

Fan tip diameter: 56.5 in

Length, flange to flange: 108 in

Takeoff thrust: 22,000 - 24,000 lb

Flat rated temperature: 86° F

Bypass ratio: 4.9

Overall pressure ratio: 26.6

Pratt & Whitney PW6000 on the Airbus A318 (video)

Originally the new PW6000 had a 5-stage high-pressure compressor, but tests revealed that this initial high pressure compressor did not meet promised fuel burn performance. To address the problem, Pratt & Whitney re-certified an updated design using a 6-stage high pressure compressor designed by MTU Aero Engines in order to achieve promised performance.

Specifications for the PW6000

Fan tip diameter: 56.5 in

Length, flange to flange: 108 in

Takeoff thrust: 22,000 - 24,000 lb

Flat rated temperature: 86° F

Bypass ratio: 4.9

Overall pressure ratio: 26.6

Pratt & Whitney PW6000 on the Airbus A318 (video)

Saturday, October 9, 2010

Thrust Vector Control

Thrust vector control, or thrust vectoring, is the capacity of a jet engine to shift the direction of the engine thrust to control the angular velocity of an aircraft or rocket. In ballistic missiles that fly outside the atmosphere thrust vector control is the primary means of orientation control.

Thrust vectoring was originally conceived to provide upward vertical thrust as a means to give aircraft vertical or short takeoff and landing ability. Subsequently, it was realized that using vectored thrust in combat situations enabled aircraft to perform various maneuvers not available to conventional-engined planes. To perform turns, aircraft that use no thrust vectoring must rely on only aerodynamic control surfaces, such as ailerons or flaps; craft with vectoring must still use control surfaces, but to a lesser extent.

Operational vectored thrust aircraft use turbofans with rotating nozzles or vanes to deflect the exhaust stream. This method can successfully deflect thrust through as much as 90 degrees, relative to the aircraft centerline. However, the engine must be sized for vertical lift, rather than normal flight, which results in a weight penalty. Afterburning (or Plenum Chamber Burning, PCB, in the bypass stream) is difficult to incorporate and is impractical for take-off and landing thrust vectoring, because the very hot exhaust can damage runway surfaces. Without afterburning it is hard to reach supersonic flight speeds. The best known example of thrust vectoring is the Rolls-Royce Pegasus engine used in the Hawker Siddeley Harrier, as well as in the AV-8B Harrier II variant.

Widespread use of thrust vectoring for enhanced maneuverability in Western production-model fighter aircraft would have to wait until the 21st century, and the deployment of the Lockheed Martin F-22 Raptor fifth-generation jet fighter, with its afterburning, thrust-vectoring Pratt & Whitney F119 turbofan.

Thrust vector control for many liquid rockets is achieved by gimballing the rocket engine. This often involves moving the entire combustion chamber and outer engine bell, or even the entire engine assembly including the related fuel and oxidizer pumps. Such a system was used on the Saturn V and is employed on the space shuttle.

Thrust vectoring was originally conceived to provide upward vertical thrust as a means to give aircraft vertical or short takeoff and landing ability. Subsequently, it was realized that using vectored thrust in combat situations enabled aircraft to perform various maneuvers not available to conventional-engined planes. To perform turns, aircraft that use no thrust vectoring must rely on only aerodynamic control surfaces, such as ailerons or flaps; craft with vectoring must still use control surfaces, but to a lesser extent.

Operational vectored thrust aircraft use turbofans with rotating nozzles or vanes to deflect the exhaust stream. This method can successfully deflect thrust through as much as 90 degrees, relative to the aircraft centerline. However, the engine must be sized for vertical lift, rather than normal flight, which results in a weight penalty. Afterburning (or Plenum Chamber Burning, PCB, in the bypass stream) is difficult to incorporate and is impractical for take-off and landing thrust vectoring, because the very hot exhaust can damage runway surfaces. Without afterburning it is hard to reach supersonic flight speeds. The best known example of thrust vectoring is the Rolls-Royce Pegasus engine used in the Hawker Siddeley Harrier, as well as in the AV-8B Harrier II variant.

Widespread use of thrust vectoring for enhanced maneuverability in Western production-model fighter aircraft would have to wait until the 21st century, and the deployment of the Lockheed Martin F-22 Raptor fifth-generation jet fighter, with its afterburning, thrust-vectoring Pratt & Whitney F119 turbofan.

Thrust vector control for many liquid rockets is achieved by gimballing the rocket engine. This often involves moving the entire combustion chamber and outer engine bell, or even the entire engine assembly including the related fuel and oxidizer pumps. Such a system was used on the Saturn V and is employed on the space shuttle.

Thrust vectoring on an F-22

Friday, October 8, 2010

Rolls Royce RB211

The Rolls-Royce RB211 was a turbofan engine developed by the British firm Rolls-Royce to power the Lockheed L-1011. It first ran on this aircraft in 1970. The RB211 could generate 40,600 lb (270 kilonewtons) thrust. The costs of development forced Rolls-Royce into bankruptcy, but it was nationalized by the British government. The RB211 was also used for land-based power generation; the first engine manufactured for this purpose was the RB211-22.

Specifications for the Roll-Royce RB211-22

Triple-spool high-bypass-ratio 5.0

Single-stage wide-chord fan

Seven-stage IP compressor

Six-stage HP compressor

Single annular combustor with 18 fuel burners

Single-stage HP turbine

Single-stage IP turbine

Three-stage LP turbine

Specifications for the Roll-Royce RB211-22

Triple-spool high-bypass-ratio 5.0

Single-stage wide-chord fan

Seven-stage IP compressor

Six-stage HP compressor

Single annular combustor with 18 fuel burners

Single-stage HP turbine

Single-stage IP turbine

Three-stage LP turbine

Thursday, October 7, 2010

General Electric F101 Turbofan

The General Electric F101 was an aircraft turbofan jet engine designed and manufactured by General Electric to power the US Air Force B-1 bomber. The F101 was the first turbofan engine with an afterburner (augmentor) produced by General Electric. It was fitted with a one-stage low pressure compressor, a nine-stage high pressure compressor, a one-stage high pressure turbine, and a two-stage low pressure turbine. With an overall pressure ratio of 26.8:1, the turbofan F101 could produce a thurst of 31,000 lb (138kN) using afterburner. The F101 was later developed into the General Electric F110 and the CFM International CFM56.

Specifications of the General Electric F101-GE-102

Type: axial-flow turbofan engine

Diameter: 55 in. (1.40 m)

Length: 181 in. (4.60 m)

Dry weight: 4,400 lbf (1995 kg)

Combustors: Annular

Compressor: axial, 1-stage fan, 1-stage low pressure compressor, 9-stage high pressure compressor

Turbine: 1-stage high pressure turbine, 2-stage low pressure turbine

Maximum power output: 31,000 lb (138 kN) (with afterburner)

Overall pressure ratio: 26.8:1

Specific fuel consumption: 2.46 lb/lbf-hr (max thrust)

Thrust-to-weight ratio: 7.04:1 (afterburner)

Specifications of the General Electric F101-GE-102

Type: axial-flow turbofan engine

Diameter: 55 in. (1.40 m)

Length: 181 in. (4.60 m)

Dry weight: 4,400 lbf (1995 kg)

Combustors: Annular

Compressor: axial, 1-stage fan, 1-stage low pressure compressor, 9-stage high pressure compressor

Turbine: 1-stage high pressure turbine, 2-stage low pressure turbine

Maximum power output: 31,000 lb (138 kN) (with afterburner)

Overall pressure ratio: 26.8:1

Specific fuel consumption: 2.46 lb/lbf-hr (max thrust)

Thrust-to-weight ratio: 7.04:1 (afterburner)

Wednesday, October 6, 2010

How a Turbofan Engine Works

A turbofan engine is an axial-flow jet engine based around a gas turbine in which the core engine is surrounded by a fan in the front and a jet exhaust nozzle. Part of the airstream from the ducted fan passes through the core, providing oxygen to burn fuel to create power. In a turbofan the extra air flow bypasses the engine core and mixes with the faster stream from the core, significantly reducing exhaust noise. The rather slower bypass airflow produces thrust more efficiently than the high-speed air from the core, and this reduces the specific fuel consumption. A turbofan engine is the most modern variation of the basic gas turbine engine.

Modern turbofans evolved from the 2-spool axial-flow turbojet engine, essentially by increasing the relative size of the Low Pressure (LP) Compressor to the point where some (if not most) of the air exiting the unit actually bypasses the core (or gas-generator) stream, passing through the main combustor. This bypass air either expands through a separate propelling nozzle, or is mixed with the hot gases leaving the Low Pressure (LP) Turbine, before expanding through a Mixed Stream Propelling Nozzle. Owing to a lower jet velocity, a modern civil turbofan is quieter than the equivalent turbojet.

Depending on specific thrust, ducted fans operate best from about 400 to 2000 km/h (250 to 1300 mph), which is why turbofans are the most common type of engine for aviation use today in airliners as well as subsonic/supersonic military fighter and trainer aircraft. It should be noted, however, that turbofans use extensive ducting to force incoming air to subsonic velocities (thus reducing shock waves throughout the engine).

Modern turbofans evolved from the 2-spool axial-flow turbojet engine, essentially by increasing the relative size of the Low Pressure (LP) Compressor to the point where some (if not most) of the air exiting the unit actually bypasses the core (or gas-generator) stream, passing through the main combustor. This bypass air either expands through a separate propelling nozzle, or is mixed with the hot gases leaving the Low Pressure (LP) Turbine, before expanding through a Mixed Stream Propelling Nozzle. Owing to a lower jet velocity, a modern civil turbofan is quieter than the equivalent turbojet.

Depending on specific thrust, ducted fans operate best from about 400 to 2000 km/h (250 to 1300 mph), which is why turbofans are the most common type of engine for aviation use today in airliners as well as subsonic/supersonic military fighter and trainer aircraft. It should be noted, however, that turbofans use extensive ducting to force incoming air to subsonic velocities (thus reducing shock waves throughout the engine).

How a turbofan engine works

Tuesday, October 5, 2010

Pratt & Whitney F119

The Pratt & Whitney F119 is an axial-flow, turbofan engine designed and manufactured by Pratt & Whitney. The F119, or PW5000, powers the F-22 Raptor fighter aircraft. It is the first jet engine developed to fly at supersonic speed without the use of afterburner. The F119 is fitted with two-dimensional pitch vectoring exhaust nozzles, which direct the engine thrust ± 20° in the pitch axis. This feature endows the F-22 Raptor with enhanced maneuverability. Pratt & Whitney's innovative titanium alloy increases stator durability, allowing the engine to run hotter and faster for greater thrust and efficiency. This heat-resistant titanium alloy protects aft components, permitting greater thrust and durability.

The F119 has a maximum thrust of 35,000 lbf, allowing a sustained supersonic speed of Mach 1.75. The three-stage integrally bladed fan of the F119 is powered by a single-stage low-pressure turbine. The engine’s counterrotating core is fitted with an aerodynamically efficient six-stage high-pressure compressor, which is driven by a single-stage high-pressure turbine, featuring the latest single-crystal superalloy blades and advanced cooling technologies. The F119 has been developed into the F135 engine, which power the F-35 fighter aircraft.

Specifications for the Pratt & Whitney F119

Type: axial-flow, twin-spool, turbofan engine

Diameter: 50 in (1,29 m)

Length: 16 ft 11 in (5.16 m)

Dry weight: classified

Compressor: Axial 3-stage low-pressure compressor; 6-stage high-pressure compressor

Combustors: Short, annular combustor

Turbine: single stage high pressure turbine; two stage low pressure turbine

Maximum thrust: more than 35,000 lbf (156 kN), with afterburner

Thrust-to-weight ratio: 9:1

The F119 has a maximum thrust of 35,000 lbf, allowing a sustained supersonic speed of Mach 1.75. The three-stage integrally bladed fan of the F119 is powered by a single-stage low-pressure turbine. The engine’s counterrotating core is fitted with an aerodynamically efficient six-stage high-pressure compressor, which is driven by a single-stage high-pressure turbine, featuring the latest single-crystal superalloy blades and advanced cooling technologies. The F119 has been developed into the F135 engine, which power the F-35 fighter aircraft.

Specifications for the Pratt & Whitney F119

Type: axial-flow, twin-spool, turbofan engine

Diameter: 50 in (1,29 m)

Length: 16 ft 11 in (5.16 m)

Dry weight: classified

Compressor: Axial 3-stage low-pressure compressor; 6-stage high-pressure compressor

Combustors: Short, annular combustor

Turbine: single stage high pressure turbine; two stage low pressure turbine

Maximum thrust: more than 35,000 lbf (156 kN), with afterburner

Thrust-to-weight ratio: 9:1

Monday, October 4, 2010

Pratt & Whitney PW2000

The Pratt & Whitney PW2000 is an axial-flow turbofan engine developed by Pratt & Whitney to power the Boeing 757. Also known as the F117 by the military, the PW2000 had a thrust range between 37,000 and 43,000 lbf. This turbofan engine was fitted with a directed-flow thrust reverser capable of being deployed in flight. On the ground, the thrust reverser can reverse a fully-loaded aircraft up a two-degree slope.

The PW2000 was a two-spool, annular combustion, electronically-controlled turbine engine, which was the first designed to certify a Full Authority Digital Engine Control (FADEC) system available for civil aviation use. The PW2000 has been built in three variants: the PW2037, which powered the Boeing 757-200; the PW2040; and the PW2043 with a thrust of 43,000 lbf (190 kN).

Used on the C-17 Globemaster III aircraft, the F117-PW-100 engine is the military version of Pratt & Whitney’s PW2000 commercial engine. Because the F117 is derived from a commercial application, it meets all current and anticipated commercial engine requirements for low noise and exhaust emissions.

Specifications of the PW2000

Type: axial-flow tubrofan engine

Length: 141.4 inches (3,592 mm)

Diameter: 78.5 inches (1,994 mm)

Compressor: Axial

Combustors: Annular

Turbine: 8 stage axial

Maximum thrust: 43,000 pounds-force (190 kN)

Overall pressure ratio: 27.6-31.2

The PW2000 was a two-spool, annular combustion, electronically-controlled turbine engine, which was the first designed to certify a Full Authority Digital Engine Control (FADEC) system available for civil aviation use. The PW2000 has been built in three variants: the PW2037, which powered the Boeing 757-200; the PW2040; and the PW2043 with a thrust of 43,000 lbf (190 kN).

Used on the C-17 Globemaster III aircraft, the F117-PW-100 engine is the military version of Pratt & Whitney’s PW2000 commercial engine. Because the F117 is derived from a commercial application, it meets all current and anticipated commercial engine requirements for low noise and exhaust emissions.

Specifications of the PW2000

Type: axial-flow tubrofan engine

Length: 141.4 inches (3,592 mm)

Diameter: 78.5 inches (1,994 mm)

Compressor: Axial

Combustors: Annular

Turbine: 8 stage axial

Maximum thrust: 43,000 pounds-force (190 kN)

Overall pressure ratio: 27.6-31.2

Sunday, October 3, 2010

Subaru Boxer Engine

The Subaru Boxer engine is a piston engine designed by the Japanese car maker Subaru. The Subaru Boxer engine stands out from the type of engine which can be found in a car. Instead of pistons moving straight up and down, or at an angle like most engines, the Subaru Boxer pistons are laid flat and move parallel to the ground. This can be seen on the Subaru Boxer engine 3D animation down below. The unique punch, counter-punch action is inherently smoother, and the low, horizontal layout is more balanced and stable. And what's more, its alignment allows to feed power directly into the Subaru Symmetrical All-Wheel Drive system with maximum efficiency. The Subaru Boxer Engine improves stability and control by lowering a Subaru's center of gravity. The Boxer produces very little vibration, allowing for better riding comfort and improved engine durability.

Saturday, October 2, 2010

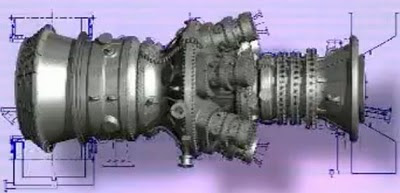

MS5002E Gas Turbine

The MS5002E Gas Turbine is an axial-flow jet engine developed by General Electric for both power generation and mechanical drive applications. This gas turbine belong to 30 MW-class machine and was designed for low environmental impact and high reliability. The MS5002E has a stable firing temperature, offering emission levels as low as 25 ppm through the use of a Dry Low NOx emission combustion system derived from the GE DLN2 combustion technology. The turbine enclosure is integrated with the baseplate, which provides maximum accessibility for maintenance.

Specifications for the MS5002E

Type: axial-flow gas turbine

Compressor: eleven-stage axial compressor

Pressure ratio 17:1

Combustor: reverse flow, can-annular combustion system with six chambers

Turbine: two-stage reaction type HP turbine

Weight: 67 tons (turbine package) and 47 tons (auxiliary package)

Output: 40,901 shp (30,500 kW)

Exhaust Flow: 225 lb/sec (102 kg/sec)

Heat Rate: 6,946 Btu/shp-h (9,825 kJ/kWh)

Exhaust Temperature: 901 F (483 C)

MS5002E Animation Video

Specifications for the MS5002E

Type: axial-flow gas turbine

Compressor: eleven-stage axial compressor

Pressure ratio 17:1

Combustor: reverse flow, can-annular combustion system with six chambers

Turbine: two-stage reaction type HP turbine

Weight: 67 tons (turbine package) and 47 tons (auxiliary package)

Output: 40,901 shp (30,500 kW)

Exhaust Flow: 225 lb/sec (102 kg/sec)

Heat Rate: 6,946 Btu/shp-h (9,825 kJ/kWh)

Exhaust Temperature: 901 F (483 C)

MS5002E Animation Video

Axial-flow Engine

An axial-flow engine is a jet engine in which the general flow of air is along the longitudinal axis of the engine. A turbojet engine that utilizes an axial-flow compressor and turbine. An Axial-flow engine is built around a long horizontal axis, with a compressor on one end, and a turbine on the other end. The single combustion chamber is located between them. The hot gases, which are the product of combustion, are blown rearwards, propelling the turbine as they provide thrust by the principle of reaction.

Axial Flow Engine

Axial-flow Engine Animation

Friday, October 1, 2010

CFM56 Turbine

The CFM56 is a turbofan aircraft turbine manufactured by CFM International (CFMI), which is a joint venture between GE Aviation of the United States and Snecma of France. The CFM56 has a thrust range of 18,500 to 34,000 pound-force (lbf) (80 to 150 kilonewtons (kN)). Also known by the US military designation F108, the CFM56 first ran in 1974. Since then more than 20,000 units have been built in five major variants: 1) CFM56-2 series, which is widely utilized in military applications (in the KC135 and the EC Mercury aircraft); 2) the CFM56-3, which was designed for Boeing 737-300/-400/-500 series aircraft; 3) the CFM56-4 series was a proposed improved version of the CFM56-2 designed for the Airbus A320 family of aircraft; 4) the CFM56-5 series, which was designed for the Airbus aircraft and has a very wide thrust rating of between 22,000 and 34,000 lbf (97.9 and 151 kN); 5) the CFM56-7 powers the Boeing 737 Next Generation series (737-600/-700/-800/-900).

Specifications of the CFM56-7 Turbofan Engine

Type: Twin-spool, high-bypass turbofan

Length: 98.7 in (2.5 m)

Diameter: 61 in (1.55 m) (fan)

Weight: 5,216 lb (2,366 kg) (dry)

Compressor: Single-stage fan, 3-stage low-pressure compressor, 9-stage high-pressure compressor

Combustors: one annular combustor

Turbine: Single-stage high-pressure turbine, 4-stage low-pressure turbine

Maximum thrust: 19,500 lbf (86.7 kN)

Overall pressure ratio: 32.8:1

Bypass ratio: 5.5:1

Thrust-to-weight ratio: 3.7:1

CFM56 Turbine Animation

Specifications of the CFM56-7 Turbofan Engine

Type: Twin-spool, high-bypass turbofan

Length: 98.7 in (2.5 m)

Diameter: 61 in (1.55 m) (fan)

Weight: 5,216 lb (2,366 kg) (dry)

Compressor: Single-stage fan, 3-stage low-pressure compressor, 9-stage high-pressure compressor

Combustors: one annular combustor

Turbine: Single-stage high-pressure turbine, 4-stage low-pressure turbine

Maximum thrust: 19,500 lbf (86.7 kN)

Overall pressure ratio: 32.8:1

Bypass ratio: 5.5:1

Thrust-to-weight ratio: 3.7:1

CFM56 Turbine Animation

Subscribe to:

Posts (Atom)