The TF34 is a twin-shaft turbofan jet engine developed by General Electric to power the S-3 Viking and the A-10 Thunderbolt II. The GE TF34 consists of a single-stage fan, 14-stage high pressure (HP) compressor, 4-stage low pressure (LP) turbine, a 2-stage high pressure (HP) turbine, and an annular combustor. The TF34-GE-400A is rated at 9,275 lbf (41.26 KN) static thrust. Designed in 1967, the TF34 first flew in 1971. It is used by the U.S. Air Force A-10 and had a growing civil market. The civil version of the TF34 was designated the CF34.

More than 460 TF34 engines are in service today with the US Navy and more than 1,050 are in service with the US Air Force. With more than 11 million fleet hours, the TF34 is projected to remain in service beyond 2028.

Specifications of the General Electric TF34

Type: axial flow bypass turbofan engine

Length: 2.62 m

Diameter: 1.12 m

Dry weight: 758 kg

Compressor: 14-stage compressor

Turbine: 4-stage LP turbine; 2-stage HP turbine

Combustor: annular

Maximum thrust: 9,275 lb

Mass flow: 338 lbs/sec

Power-to-weight ratio:

Showing posts with label Engines. Show all posts

Showing posts with label Engines. Show all posts

Wednesday, October 20, 2010

Tuesday, October 19, 2010

Allison J102

The Allison J102 was a supersonic missile turbojet engine developed by the Allison Engine Company. The J102 was an axial flow turbojet which was first run in March 1991. In 1997 it was being considered for use in a sea-skimming supersonic target for the United States Navy.

The J102 was a reaction engine which produced thrust by the expulsion of a high-speed gas exhaust. It was created by high pressure (10-200 bar) combustion of solid propellants, consisting of fuel and oxidiser components, within a combustion chamber. The fluid exhaust was then passed through a propelling nozzle which typically used the heat energy of the gas to accelerate the exhaust to very high speed, and the reaction to this pushed the engine in the opposite direction.

The J102 was a reaction engine which produced thrust by the expulsion of a high-speed gas exhaust. It was created by high pressure (10-200 bar) combustion of solid propellants, consisting of fuel and oxidiser components, within a combustion chamber. The fluid exhaust was then passed through a propelling nozzle which typically used the heat energy of the gas to accelerate the exhaust to very high speed, and the reaction to this pushed the engine in the opposite direction.

Monday, October 18, 2010

Afterburner (Jet Engine)

A jet engine afterburner is an extended exhaust section which contains extra fuel injectors. When the afterburner is turned on, fuel is injected, which ignites readily due to the relatively high temperature of the incoming gases. The resulting combustion process increases the afterburner exit (nozzle entry) temperature significantly, resulting in a steep increase in engine net thrust. Thus, jet engines achieve additional thrust by directly injecting fuel at the engine exhaust. The afterburner gives the aircraft a rocket-like boost as the fuel ignites in the exhaust chamber. The tradeoff is higher fuel consumption, a greater amount of heat, and consequently, greater visibility to the enemy.

The purpose of an afterburner is to provide a temporary increase in thrust, both for supersonic flight and for takeoff, as the high wing loading typical of supersonic aircraft designs means that take-off speed is very high. On military aircraft the extra thrust is also useful for combat situations. This is achieved by injecting additional fuel into the jet pipe downstream of the turbine. The advantage of afterburning is significantly increased thrust; the disadvantage is its very high fuel consumption and inefficiency, though this is often regarded as acceptable for the short periods during which it is usually used.

The purpose of an afterburner is to provide a temporary increase in thrust, both for supersonic flight and for takeoff, as the high wing loading typical of supersonic aircraft designs means that take-off speed is very high. On military aircraft the extra thrust is also useful for combat situations. This is achieved by injecting additional fuel into the jet pipe downstream of the turbine. The advantage of afterburning is significantly increased thrust; the disadvantage is its very high fuel consumption and inefficiency, though this is often regarded as acceptable for the short periods during which it is usually used.

Afterburner Run on a Jet Aircraft

Sunday, October 17, 2010

Rolls Royce/Snecma Olympus 593

The Rolls-Royce/Snecma Olympus 593 was an axial-flow turbojet engine which was developed by the Birtish firm Rolls Royce and the French Snecma to power the Concorde aircraft. The Olympus 593 consisted of a seven-stage low pressure compressor, a seven-stage high pressure compressor, a single-stage high pressure turbine, and a single-stage low pressure turbine. It had an annular chamber with sixteen vaporizing burners, each with twin outlets.

The jet engine draws air in at the front and compresses it. The air then combines with fuel and the engine burns the resulting mixture. The combustion greatly increases the volume of the gases which are then exhausted out of the rear of the engine. The Olympus 593 engine took this gas jet and passed it through straightening vanes - to remove swirl. This gas jet then entered the afterburning jet pipe where a ring of fuel injectors sprayed fuel onto the hot exhaust gases. The resulting combustion greatly improved thrust, although it also led to high fuel consumption. The afterburner was thus only used at takeoff and from just below Mach 1 up to Mach 1.7, the engine supercruised above that speed.

Using the BAC TSR-2's Olympus 320 as a basis for development, the Olympus 593 project began in 1964. Bristol Siddeley of the UK and Snecma Moteurs of France were to share the project. In 1966, Rolls Royce acquired Bristol Siddeley and continued with the project. Development of the original Olympus and engine accessories was under Bristol Siddeley, while Snecma was responsible for the variable engine inlet system, the exhaust nozzle/thrust reverser, the afterburner and the noise attenuation system. Britain was to have a larger share in production of the Olympus 593 as France had a larger share in fuselage production.

Specifications

Type: axial-flow jet engine

Length: 4039 mm (159 in)

Diameter: 1212 mm (47.75 in)

Dry weight: 3175 kg (7,000 lb)

Compressor: Axial flow, 7-stage low pressure, 7-stage high pressure

Turbine: High pressure single stage, low pressure single stage

Combustors: Nickel alloy construction annular chamber, 16 vaporizing burners, each with twin outlets

Maximum thrust: wet: 169.2 kN (38,050 lbf) dry: 139.4 kN (31,350 lbf)

Overall pressure ratio: 15.5:1

Specific fuel consumption: 1.195 (cruise), 1.39 (SL) lb/(h·lbf)

Thrust-to-weight ratio: 5.4:1

The jet engine draws air in at the front and compresses it. The air then combines with fuel and the engine burns the resulting mixture. The combustion greatly increases the volume of the gases which are then exhausted out of the rear of the engine. The Olympus 593 engine took this gas jet and passed it through straightening vanes - to remove swirl. This gas jet then entered the afterburning jet pipe where a ring of fuel injectors sprayed fuel onto the hot exhaust gases. The resulting combustion greatly improved thrust, although it also led to high fuel consumption. The afterburner was thus only used at takeoff and from just below Mach 1 up to Mach 1.7, the engine supercruised above that speed.

Using the BAC TSR-2's Olympus 320 as a basis for development, the Olympus 593 project began in 1964. Bristol Siddeley of the UK and Snecma Moteurs of France were to share the project. In 1966, Rolls Royce acquired Bristol Siddeley and continued with the project. Development of the original Olympus and engine accessories was under Bristol Siddeley, while Snecma was responsible for the variable engine inlet system, the exhaust nozzle/thrust reverser, the afterburner and the noise attenuation system. Britain was to have a larger share in production of the Olympus 593 as France had a larger share in fuselage production.

Specifications

Type: axial-flow jet engine

Length: 4039 mm (159 in)

Diameter: 1212 mm (47.75 in)

Dry weight: 3175 kg (7,000 lb)

Compressor: Axial flow, 7-stage low pressure, 7-stage high pressure

Turbine: High pressure single stage, low pressure single stage

Combustors: Nickel alloy construction annular chamber, 16 vaporizing burners, each with twin outlets

Maximum thrust: wet: 169.2 kN (38,050 lbf) dry: 139.4 kN (31,350 lbf)

Overall pressure ratio: 15.5:1

Specific fuel consumption: 1.195 (cruise), 1.39 (SL) lb/(h·lbf)

Thrust-to-weight ratio: 5.4:1

Saturday, October 16, 2010

Pratt & Whitney J75

The J75 was an axial-flow, twin-spool, turbojet engine developed by Pratt & Whitney from the J57. The J75 powered the F-105 Thunderchief, Boeing 707, F-106 Delta Dart, and the Lockheed U2. It first ran on an aircraft in 1955. The Pratt & Whitney could produce up to 24,500 lbf thrust. In civilian service, it was known as the JT4A and the GG4, which were used in a variety of stationary power generation applications.

After its relatively short lifetime in the aircraft role, the J75 found more enduring use in the naval role, where it was produced in a variety of models between 18,000 and 22,000 hp. Well-known uses include the first all-turbine warships, the Canadian Iroquois class destroyers, as well as the United States Coast Guard's Hamilton class cutters, and it was considered for the US Navy's Asheville class gunboat.

After its relatively short lifetime in the aircraft role, the J75 found more enduring use in the naval role, where it was produced in a variety of models between 18,000 and 22,000 hp. Well-known uses include the first all-turbine warships, the Canadian Iroquois class destroyers, as well as the United States Coast Guard's Hamilton class cutters, and it was considered for the US Navy's Asheville class gunboat.

Friday, October 15, 2010

Allison J71

The Allison J71 was an axial-flow jet engine, designed and built by Allison Engine Company in the United States. The development of the J71 began in 1948 as a modified J35 and was originally designated the J35-A-23. The Allison J71 turbojet powered the Douglas B-66 Destroyer and the McDonnell F3H-2 Demon after the failed Westinghouse J40 proved unworkable. The prototype P6M SeaMasters were also fitted with this engine.

Specifications for the Allison J71-A-2E

Type: axial-flow turbojet with afterburner

Length: 23.9 ft

Diameter: 3.5 ft

Weight: 1,855 kg

Compressor: 16-stage axial compressor

Turbine: 3-stage

Thrust: 14,000 lb (62.3 kN) with afterburner

Specifications for the Allison J71-A-2E

Type: axial-flow turbojet with afterburner

Length: 23.9 ft

Diameter: 3.5 ft

Weight: 1,855 kg

Compressor: 16-stage axial compressor

Turbine: 3-stage

Thrust: 14,000 lb (62.3 kN) with afterburner

Thursday, October 14, 2010

Rolls-Royce RB.183 Tay

The Rolls-Royce RB.183 Tay is a twin-spool, high bypass turbofan engine manufactured by Rolls Royce for the Fokker 70 and Fokker 100 aircraft. The RB.183 Tay consists of a twenty-two blade titanium fan, three-stage Intermediate pressure compressor, twelve-stage High pressure compressor, two-stage high pressure turbine, and three-stage low pressure turbine. This aircraft engine was developed from the RB.163 Spey, using scaled down low-pressure components from the RB.211 to produce versions with a bypass ratio of 3.1:1 or greater. The engine was first run in August 1984.

Specifications for the Rolls Royce RB.183 Tay

Type: high bypass turbofan jet engine

Length: 94.7 in (2405.4 mm)

Diameter: 44 in (1117.6 mm) (fan diameter)

Dry weight: 3,310 lb (1501.4 kg)

Bypass ratio: 3.04

Compressor: Single stage fan, 3-stage LP compressor and 12-stage HP compressor

Turbine: 2-stage HP turbine and 3-stage LP turbine

Combustors: 10 cannular combustion chambers

Maximum thrust: 13,850 lbf (62.82 kN)

Turbine inlet temperature: 735 degrees C (maximum continuous)

Thrust-to-weight ratio: 4.2

Rolls-Royce Tay

Specifications for the Rolls Royce RB.183 Tay

Type: high bypass turbofan jet engine

Length: 94.7 in (2405.4 mm)

Diameter: 44 in (1117.6 mm) (fan diameter)

Dry weight: 3,310 lb (1501.4 kg)

Bypass ratio: 3.04

Compressor: Single stage fan, 3-stage LP compressor and 12-stage HP compressor

Turbine: 2-stage HP turbine and 3-stage LP turbine

Combustors: 10 cannular combustion chambers

Maximum thrust: 13,850 lbf (62.82 kN)

Turbine inlet temperature: 735 degrees C (maximum continuous)

Thrust-to-weight ratio: 4.2

Rolls-Royce Tay

Wednesday, October 13, 2010

Rolls-Royce Trent 700

The Rolls-Royce Trent 700 is an axial-flow, tripple-spool, turbofan engine which was developed by Rolls Royce from the RB.211 to power the Airbus 330. It belongs to the family of Trent engines. The Trent 700 first ran in August 1990, and certification was achieved in January 1994. 90 minutes ETOPS approval was achieved in March 1995, and this was extended to 120 minutes in December 1995 and 180 minutes in May 1996.

Specifications for the Rolls Royce Trent 700

Type: Triple-spool high bypass turbofan

Length: 3.91 m (154 in)

Diameter: 2.47 m (97 in)

Dry weight:

Bypass ratio: 5.0:1

Compressor: Eight-stage IP compressor, six-stage HP compressor

Turbine: Single-stage HP turbine, single-stage IP turbine, four-stage LP turbine

Combustors: Single annular combustor with 24 fuel injectors

Specifications for the Rolls Royce Trent 700

Type: Triple-spool high bypass turbofan

Length: 3.91 m (154 in)

Diameter: 2.47 m (97 in)

Dry weight:

Bypass ratio: 5.0:1

Compressor: Eight-stage IP compressor, six-stage HP compressor

Turbine: Single-stage HP turbine, single-stage IP turbine, four-stage LP turbine

Combustors: Single annular combustor with 24 fuel injectors

Rolls Royce Trent Certification

Tuesday, October 12, 2010

Rolls Royce Pegasus

The Rolls-Royce Pegasus was a twin-spool turbofan engine which was developed by Bristol Siddeley to power the Hawker Siddeley Harrier and the BAE Sea Harrier aircraft. The Pegasus first ran in September 1959, but its first and difficult transition from static hover to conventional flight took place on September 8, 1961. It was manufactured by Rolls Royce Plc, totaling over 1,250 engines in different versions: Pegasus 2; 5; 6, which was built for the first Harriers (19,000lbf), entering service 1969; 10; 11, which powered the RAF's Hawker Siddeley Harrier GR.3.

The Rolls Royce Pegasus was a two-shaft design, featuring a 3-stage low pressure compressor and a 8-stage high pressure compressor, driven by a 2-stage low pressure and a 2-stage high pressure turbine respectively. Unusually the low pressure and high pressure spools rotate in opposite directions to greatly reduce the gyroscopic effects which would otherwise hamper low speed handling. The engine utilizes a simple thrust vectoring system with four swivelling nozzles, giving the Harrier thrust both for lift and forward propulsion, allowing for STOVL flight.

Specifications for the Rolls-Royce Pegasus 11

Type: twin-spool turbofan

Length: 137 in (3.480 m)

Diameter: 48 in (1.219 m)

Dry weight: 3,960 lb (1,796 kg)

Compressor: 3-stage low pressure, 8-stage high pressure axial flow

Turbine: 2-stage low pressure, 2-stage high pressure

Combustors: annular

Maximum thrust: 23,800 lbf (106 kN)

Overall pressure ratio: 16.3:1

Specific fuel consumption: 0.76 lb/lbf-hr

Thrust-to-weight ratio: 6:1

The Rolls Royce Pegasus was a two-shaft design, featuring a 3-stage low pressure compressor and a 8-stage high pressure compressor, driven by a 2-stage low pressure and a 2-stage high pressure turbine respectively. Unusually the low pressure and high pressure spools rotate in opposite directions to greatly reduce the gyroscopic effects which would otherwise hamper low speed handling. The engine utilizes a simple thrust vectoring system with four swivelling nozzles, giving the Harrier thrust both for lift and forward propulsion, allowing for STOVL flight.

Specifications for the Rolls-Royce Pegasus 11

Type: twin-spool turbofan

Length: 137 in (3.480 m)

Diameter: 48 in (1.219 m)

Dry weight: 3,960 lb (1,796 kg)

Compressor: 3-stage low pressure, 8-stage high pressure axial flow

Turbine: 2-stage low pressure, 2-stage high pressure

Combustors: annular

Maximum thrust: 23,800 lbf (106 kN)

Overall pressure ratio: 16.3:1

Specific fuel consumption: 0.76 lb/lbf-hr

Thrust-to-weight ratio: 6:1

Monday, October 11, 2010

Rolls-Royce BR710

The Rolls-Royce BR710 was an axial-flow turbofan engine manufactured by Rolls Royce Deutschland. The BR710 ran for the first time in September 1994. It was composed of a 48in-diameter single stage fan, which was driven by a two-stage low pressure turbine, supercharging a ten-stage high pressure compressor and driven by a two-stage, air-cooled, high prussure turbine.

The BR710 was a twin shaft turbofan, entered service on the Gulfstream V aircraft in 1997 and the Bombardier Global Express in 1998. This version has also been selected to power the Gulfstream G550.

Specifications

Fan Diameter: 48.0 inches

Overall Length: 134.0 inches

Dry Weight: 4,640 lb

Thrust: 14,750-15,500 lb

The BR710 was a twin shaft turbofan, entered service on the Gulfstream V aircraft in 1997 and the Bombardier Global Express in 1998. This version has also been selected to power the Gulfstream G550.

Specifications

Fan Diameter: 48.0 inches

Overall Length: 134.0 inches

Dry Weight: 4,640 lb

Thrust: 14,750-15,500 lb

Sunday, October 10, 2010

Pratt & Whitney PW6000

The PW6000 is a turbofan engine developed by Pratt & Whitney to power the Airbus A318. It entered service in 2007 with a design thrust range of 18,000 to 24,000 lbf (82 to 109 kN). The Pratt & Whitney PW6000 is a high-bypass turbofan which was designed to significantly reduce maintenance cost and achieve weight and fuel consumption savings.

Originally the new PW6000 had a 5-stage high-pressure compressor, but tests revealed that this initial high pressure compressor did not meet promised fuel burn performance. To address the problem, Pratt & Whitney re-certified an updated design using a 6-stage high pressure compressor designed by MTU Aero Engines in order to achieve promised performance.

Specifications for the PW6000

Fan tip diameter: 56.5 in

Length, flange to flange: 108 in

Takeoff thrust: 22,000 - 24,000 lb

Flat rated temperature: 86° F

Bypass ratio: 4.9

Overall pressure ratio: 26.6

Pratt & Whitney PW6000 on the Airbus A318 (video)

Originally the new PW6000 had a 5-stage high-pressure compressor, but tests revealed that this initial high pressure compressor did not meet promised fuel burn performance. To address the problem, Pratt & Whitney re-certified an updated design using a 6-stage high pressure compressor designed by MTU Aero Engines in order to achieve promised performance.

Specifications for the PW6000

Fan tip diameter: 56.5 in

Length, flange to flange: 108 in

Takeoff thrust: 22,000 - 24,000 lb

Flat rated temperature: 86° F

Bypass ratio: 4.9

Overall pressure ratio: 26.6

Pratt & Whitney PW6000 on the Airbus A318 (video)

Friday, October 8, 2010

Rolls Royce RB211

The Rolls-Royce RB211 was a turbofan engine developed by the British firm Rolls-Royce to power the Lockheed L-1011. It first ran on this aircraft in 1970. The RB211 could generate 40,600 lb (270 kilonewtons) thrust. The costs of development forced Rolls-Royce into bankruptcy, but it was nationalized by the British government. The RB211 was also used for land-based power generation; the first engine manufactured for this purpose was the RB211-22.

Specifications for the Roll-Royce RB211-22

Triple-spool high-bypass-ratio 5.0

Single-stage wide-chord fan

Seven-stage IP compressor

Six-stage HP compressor

Single annular combustor with 18 fuel burners

Single-stage HP turbine

Single-stage IP turbine

Three-stage LP turbine

Specifications for the Roll-Royce RB211-22

Triple-spool high-bypass-ratio 5.0

Single-stage wide-chord fan

Seven-stage IP compressor

Six-stage HP compressor

Single annular combustor with 18 fuel burners

Single-stage HP turbine

Single-stage IP turbine

Three-stage LP turbine

Thursday, October 7, 2010

General Electric F101 Turbofan

The General Electric F101 was an aircraft turbofan jet engine designed and manufactured by General Electric to power the US Air Force B-1 bomber. The F101 was the first turbofan engine with an afterburner (augmentor) produced by General Electric. It was fitted with a one-stage low pressure compressor, a nine-stage high pressure compressor, a one-stage high pressure turbine, and a two-stage low pressure turbine. With an overall pressure ratio of 26.8:1, the turbofan F101 could produce a thurst of 31,000 lb (138kN) using afterburner. The F101 was later developed into the General Electric F110 and the CFM International CFM56.

Specifications of the General Electric F101-GE-102

Type: axial-flow turbofan engine

Diameter: 55 in. (1.40 m)

Length: 181 in. (4.60 m)

Dry weight: 4,400 lbf (1995 kg)

Combustors: Annular

Compressor: axial, 1-stage fan, 1-stage low pressure compressor, 9-stage high pressure compressor

Turbine: 1-stage high pressure turbine, 2-stage low pressure turbine

Maximum power output: 31,000 lb (138 kN) (with afterburner)

Overall pressure ratio: 26.8:1

Specific fuel consumption: 2.46 lb/lbf-hr (max thrust)

Thrust-to-weight ratio: 7.04:1 (afterburner)

Specifications of the General Electric F101-GE-102

Type: axial-flow turbofan engine

Diameter: 55 in. (1.40 m)

Length: 181 in. (4.60 m)

Dry weight: 4,400 lbf (1995 kg)

Combustors: Annular

Compressor: axial, 1-stage fan, 1-stage low pressure compressor, 9-stage high pressure compressor

Turbine: 1-stage high pressure turbine, 2-stage low pressure turbine

Maximum power output: 31,000 lb (138 kN) (with afterburner)

Overall pressure ratio: 26.8:1

Specific fuel consumption: 2.46 lb/lbf-hr (max thrust)

Thrust-to-weight ratio: 7.04:1 (afterburner)

Wednesday, October 6, 2010

How a Turbofan Engine Works

A turbofan engine is an axial-flow jet engine based around a gas turbine in which the core engine is surrounded by a fan in the front and a jet exhaust nozzle. Part of the airstream from the ducted fan passes through the core, providing oxygen to burn fuel to create power. In a turbofan the extra air flow bypasses the engine core and mixes with the faster stream from the core, significantly reducing exhaust noise. The rather slower bypass airflow produces thrust more efficiently than the high-speed air from the core, and this reduces the specific fuel consumption. A turbofan engine is the most modern variation of the basic gas turbine engine.

Modern turbofans evolved from the 2-spool axial-flow turbojet engine, essentially by increasing the relative size of the Low Pressure (LP) Compressor to the point where some (if not most) of the air exiting the unit actually bypasses the core (or gas-generator) stream, passing through the main combustor. This bypass air either expands through a separate propelling nozzle, or is mixed with the hot gases leaving the Low Pressure (LP) Turbine, before expanding through a Mixed Stream Propelling Nozzle. Owing to a lower jet velocity, a modern civil turbofan is quieter than the equivalent turbojet.

Depending on specific thrust, ducted fans operate best from about 400 to 2000 km/h (250 to 1300 mph), which is why turbofans are the most common type of engine for aviation use today in airliners as well as subsonic/supersonic military fighter and trainer aircraft. It should be noted, however, that turbofans use extensive ducting to force incoming air to subsonic velocities (thus reducing shock waves throughout the engine).

Modern turbofans evolved from the 2-spool axial-flow turbojet engine, essentially by increasing the relative size of the Low Pressure (LP) Compressor to the point where some (if not most) of the air exiting the unit actually bypasses the core (or gas-generator) stream, passing through the main combustor. This bypass air either expands through a separate propelling nozzle, or is mixed with the hot gases leaving the Low Pressure (LP) Turbine, before expanding through a Mixed Stream Propelling Nozzle. Owing to a lower jet velocity, a modern civil turbofan is quieter than the equivalent turbojet.

Depending on specific thrust, ducted fans operate best from about 400 to 2000 km/h (250 to 1300 mph), which is why turbofans are the most common type of engine for aviation use today in airliners as well as subsonic/supersonic military fighter and trainer aircraft. It should be noted, however, that turbofans use extensive ducting to force incoming air to subsonic velocities (thus reducing shock waves throughout the engine).

How a turbofan engine works

Tuesday, October 5, 2010

Pratt & Whitney F119

The Pratt & Whitney F119 is an axial-flow, turbofan engine designed and manufactured by Pratt & Whitney. The F119, or PW5000, powers the F-22 Raptor fighter aircraft. It is the first jet engine developed to fly at supersonic speed without the use of afterburner. The F119 is fitted with two-dimensional pitch vectoring exhaust nozzles, which direct the engine thrust ± 20° in the pitch axis. This feature endows the F-22 Raptor with enhanced maneuverability. Pratt & Whitney's innovative titanium alloy increases stator durability, allowing the engine to run hotter and faster for greater thrust and efficiency. This heat-resistant titanium alloy protects aft components, permitting greater thrust and durability.

The F119 has a maximum thrust of 35,000 lbf, allowing a sustained supersonic speed of Mach 1.75. The three-stage integrally bladed fan of the F119 is powered by a single-stage low-pressure turbine. The engine’s counterrotating core is fitted with an aerodynamically efficient six-stage high-pressure compressor, which is driven by a single-stage high-pressure turbine, featuring the latest single-crystal superalloy blades and advanced cooling technologies. The F119 has been developed into the F135 engine, which power the F-35 fighter aircraft.

Specifications for the Pratt & Whitney F119

Type: axial-flow, twin-spool, turbofan engine

Diameter: 50 in (1,29 m)

Length: 16 ft 11 in (5.16 m)

Dry weight: classified

Compressor: Axial 3-stage low-pressure compressor; 6-stage high-pressure compressor

Combustors: Short, annular combustor

Turbine: single stage high pressure turbine; two stage low pressure turbine

Maximum thrust: more than 35,000 lbf (156 kN), with afterburner

Thrust-to-weight ratio: 9:1

The F119 has a maximum thrust of 35,000 lbf, allowing a sustained supersonic speed of Mach 1.75. The three-stage integrally bladed fan of the F119 is powered by a single-stage low-pressure turbine. The engine’s counterrotating core is fitted with an aerodynamically efficient six-stage high-pressure compressor, which is driven by a single-stage high-pressure turbine, featuring the latest single-crystal superalloy blades and advanced cooling technologies. The F119 has been developed into the F135 engine, which power the F-35 fighter aircraft.

Specifications for the Pratt & Whitney F119

Type: axial-flow, twin-spool, turbofan engine

Diameter: 50 in (1,29 m)

Length: 16 ft 11 in (5.16 m)

Dry weight: classified

Compressor: Axial 3-stage low-pressure compressor; 6-stage high-pressure compressor

Combustors: Short, annular combustor

Turbine: single stage high pressure turbine; two stage low pressure turbine

Maximum thrust: more than 35,000 lbf (156 kN), with afterburner

Thrust-to-weight ratio: 9:1

Monday, October 4, 2010

Pratt & Whitney PW2000

The Pratt & Whitney PW2000 is an axial-flow turbofan engine developed by Pratt & Whitney to power the Boeing 757. Also known as the F117 by the military, the PW2000 had a thrust range between 37,000 and 43,000 lbf. This turbofan engine was fitted with a directed-flow thrust reverser capable of being deployed in flight. On the ground, the thrust reverser can reverse a fully-loaded aircraft up a two-degree slope.

The PW2000 was a two-spool, annular combustion, electronically-controlled turbine engine, which was the first designed to certify a Full Authority Digital Engine Control (FADEC) system available for civil aviation use. The PW2000 has been built in three variants: the PW2037, which powered the Boeing 757-200; the PW2040; and the PW2043 with a thrust of 43,000 lbf (190 kN).

Used on the C-17 Globemaster III aircraft, the F117-PW-100 engine is the military version of Pratt & Whitney’s PW2000 commercial engine. Because the F117 is derived from a commercial application, it meets all current and anticipated commercial engine requirements for low noise and exhaust emissions.

Specifications of the PW2000

Type: axial-flow tubrofan engine

Length: 141.4 inches (3,592 mm)

Diameter: 78.5 inches (1,994 mm)

Compressor: Axial

Combustors: Annular

Turbine: 8 stage axial

Maximum thrust: 43,000 pounds-force (190 kN)

Overall pressure ratio: 27.6-31.2

The PW2000 was a two-spool, annular combustion, electronically-controlled turbine engine, which was the first designed to certify a Full Authority Digital Engine Control (FADEC) system available for civil aviation use. The PW2000 has been built in three variants: the PW2037, which powered the Boeing 757-200; the PW2040; and the PW2043 with a thrust of 43,000 lbf (190 kN).

Used on the C-17 Globemaster III aircraft, the F117-PW-100 engine is the military version of Pratt & Whitney’s PW2000 commercial engine. Because the F117 is derived from a commercial application, it meets all current and anticipated commercial engine requirements for low noise and exhaust emissions.

Specifications of the PW2000

Type: axial-flow tubrofan engine

Length: 141.4 inches (3,592 mm)

Diameter: 78.5 inches (1,994 mm)

Compressor: Axial

Combustors: Annular

Turbine: 8 stage axial

Maximum thrust: 43,000 pounds-force (190 kN)

Overall pressure ratio: 27.6-31.2

Sunday, October 3, 2010

Subaru Boxer Engine

The Subaru Boxer engine is a piston engine designed by the Japanese car maker Subaru. The Subaru Boxer engine stands out from the type of engine which can be found in a car. Instead of pistons moving straight up and down, or at an angle like most engines, the Subaru Boxer pistons are laid flat and move parallel to the ground. This can be seen on the Subaru Boxer engine 3D animation down below. The unique punch, counter-punch action is inherently smoother, and the low, horizontal layout is more balanced and stable. And what's more, its alignment allows to feed power directly into the Subaru Symmetrical All-Wheel Drive system with maximum efficiency. The Subaru Boxer Engine improves stability and control by lowering a Subaru's center of gravity. The Boxer produces very little vibration, allowing for better riding comfort and improved engine durability.

Saturday, October 2, 2010

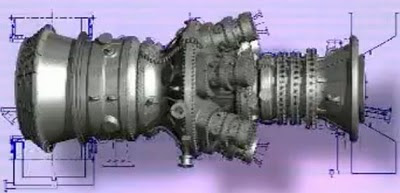

MS5002E Gas Turbine

The MS5002E Gas Turbine is an axial-flow jet engine developed by General Electric for both power generation and mechanical drive applications. This gas turbine belong to 30 MW-class machine and was designed for low environmental impact and high reliability. The MS5002E has a stable firing temperature, offering emission levels as low as 25 ppm through the use of a Dry Low NOx emission combustion system derived from the GE DLN2 combustion technology. The turbine enclosure is integrated with the baseplate, which provides maximum accessibility for maintenance.

Specifications for the MS5002E

Type: axial-flow gas turbine

Compressor: eleven-stage axial compressor

Pressure ratio 17:1

Combustor: reverse flow, can-annular combustion system with six chambers

Turbine: two-stage reaction type HP turbine

Weight: 67 tons (turbine package) and 47 tons (auxiliary package)

Output: 40,901 shp (30,500 kW)

Exhaust Flow: 225 lb/sec (102 kg/sec)

Heat Rate: 6,946 Btu/shp-h (9,825 kJ/kWh)

Exhaust Temperature: 901 F (483 C)

MS5002E Animation Video

Specifications for the MS5002E

Type: axial-flow gas turbine

Compressor: eleven-stage axial compressor

Pressure ratio 17:1

Combustor: reverse flow, can-annular combustion system with six chambers

Turbine: two-stage reaction type HP turbine

Weight: 67 tons (turbine package) and 47 tons (auxiliary package)

Output: 40,901 shp (30,500 kW)

Exhaust Flow: 225 lb/sec (102 kg/sec)

Heat Rate: 6,946 Btu/shp-h (9,825 kJ/kWh)

Exhaust Temperature: 901 F (483 C)

MS5002E Animation Video

Axial-flow Engine

An axial-flow engine is a jet engine in which the general flow of air is along the longitudinal axis of the engine. A turbojet engine that utilizes an axial-flow compressor and turbine. An Axial-flow engine is built around a long horizontal axis, with a compressor on one end, and a turbine on the other end. The single combustion chamber is located between them. The hot gases, which are the product of combustion, are blown rearwards, propelling the turbine as they provide thrust by the principle of reaction.

Axial Flow Engine

Axial-flow Engine Animation

Friday, October 1, 2010

CFM56 Turbine

The CFM56 is a turbofan aircraft turbine manufactured by CFM International (CFMI), which is a joint venture between GE Aviation of the United States and Snecma of France. The CFM56 has a thrust range of 18,500 to 34,000 pound-force (lbf) (80 to 150 kilonewtons (kN)). Also known by the US military designation F108, the CFM56 first ran in 1974. Since then more than 20,000 units have been built in five major variants: 1) CFM56-2 series, which is widely utilized in military applications (in the KC135 and the EC Mercury aircraft); 2) the CFM56-3, which was designed for Boeing 737-300/-400/-500 series aircraft; 3) the CFM56-4 series was a proposed improved version of the CFM56-2 designed for the Airbus A320 family of aircraft; 4) the CFM56-5 series, which was designed for the Airbus aircraft and has a very wide thrust rating of between 22,000 and 34,000 lbf (97.9 and 151 kN); 5) the CFM56-7 powers the Boeing 737 Next Generation series (737-600/-700/-800/-900).

Specifications of the CFM56-7 Turbofan Engine

Type: Twin-spool, high-bypass turbofan

Length: 98.7 in (2.5 m)

Diameter: 61 in (1.55 m) (fan)

Weight: 5,216 lb (2,366 kg) (dry)

Compressor: Single-stage fan, 3-stage low-pressure compressor, 9-stage high-pressure compressor

Combustors: one annular combustor

Turbine: Single-stage high-pressure turbine, 4-stage low-pressure turbine

Maximum thrust: 19,500 lbf (86.7 kN)

Overall pressure ratio: 32.8:1

Bypass ratio: 5.5:1

Thrust-to-weight ratio: 3.7:1

CFM56 Turbine Animation

Specifications of the CFM56-7 Turbofan Engine

Type: Twin-spool, high-bypass turbofan

Length: 98.7 in (2.5 m)

Diameter: 61 in (1.55 m) (fan)

Weight: 5,216 lb (2,366 kg) (dry)

Compressor: Single-stage fan, 3-stage low-pressure compressor, 9-stage high-pressure compressor

Combustors: one annular combustor

Turbine: Single-stage high-pressure turbine, 4-stage low-pressure turbine

Maximum thrust: 19,500 lbf (86.7 kN)

Overall pressure ratio: 32.8:1

Bypass ratio: 5.5:1

Thrust-to-weight ratio: 3.7:1

CFM56 Turbine Animation

Subscribe to:

Posts (Atom)